THE

ADVANCED RANKINE CYCLE ENGINE AND THE APPLICATION POTENTIAL

FOR USING THE CYCLONE ENGINE IN THE AUTOMOBILE.

JDC 05-28-10

PREFACE.

This paper is written to explore and discuss the possibilities of applying the Cyclone Rankine cycle engine to the automobile. The Cyclone engine specifically, because it alone of all the steam systems proposed, is the most advanced, has a most competitive net efficiency and could be the closest one to full scale production if sufficient funding were provided. It is not a wishful proposal, as it exists right now in various sizes. The Cyclone engine is reality.

What is also reality today is that far too many mandates by Federal and State governments are imposing flawed decisions, bad science and poor reasoning on the entire subject of the automobile, what fuels it and what power source propels it. This subject is important, as it has had a great influence on the automobile and the cost to the consumer.

There are sound reasons for again visiting the Rankine cycle steam engine and considering it for automotive and heavy truck and bus use. The world is experiencing problems with global warming and is in need of some fuel burning power source for vehicles that does not generate CO2 in either the production or the use of that fuel. These various Government mandates coming out of Washington and California appear to be more like panic driven guesses and political posturing than sound and cold engineering reasoning. Quite often side issues greatly harm the power sources they propose.

This steam engine system offers massive starting torque, eliminating the need for a transmission in most cases. The new burner systems are totally pollution free when burning pure bio algae and plant fuel oils. The simplicity of the system, when designed properly, offers a reduction in prime costs. With the system operating conditions that the Cyclone uses, the net cycle efficiency is now equal and better than the spark ignited IC engine automatic transmission package and approaching that of the Diesel engine. This engine exhibits a notable reduction in moving parts and a good cost savings would be evident when in production.

Basically, what with the design and material improvements available today, the Rankine cycle engine cannot continue to be ignored. It does offer a solution when the design is correct.

INTRODUCTION.

The steam powered automobile has existed since the actual beginning of that form of transport.

In the ending years of the 19th Century and the start of the 20th Century, steam was the desired power source. It was understood and used world wide in all sizes and was accepted. The internal combustion engine (IC) was a cantankerous and unreliable power source until the various automobile manufacturers took it under intense development and one by one eliminated the problems. Then it became the accepted power source and the steamer was relegated to the background, except for a few companies and enthusiasts who refused to bow to this way of thinking and to abandon the features that only steam offered. Today that dream is still alive.

The steam car as it exists now has not received the engineering improvements where existing material and engineering advances since WW-II, plus the revised fuel-burning conditions, will amply demonstrate the dramatic gains that are now reality. To date, since the government funded clean air car projects of the 1960-1985 period and the amateur work going on today, such past steam power systems do not provide the necessary improvements required to ensure either commercial success or the high level of pollution elimination that is demanded today, let alone efficient fuel use.

The old antique steamers and most of the projects to date, show only that Band-Aids and some detail advances in specific areas have been applied to basically 19th century technology. Quite a few proposed border on the technically absurd. What was necessary was a total review in all areas of vehicle Rankine cycle engineering, a clean sheet of paper and then concentration on advancing the work in those problem areas. The Cyclone Power Technologies Company Inc. has done this and the new developments are showing dramatic improvement.

The Cyclone Rankine cycle steam engine does not use any magical or unknown features that were just discovered after years of being hidden. What it does is combine known and advanced thermodynamic and engineering design concepts into one unit. This required many years and large funding to develop and demonstrate a working system.

There are several areas of this engineering that needed drastic improvements.

Increased Power Density. This means increasing by a large amount the push on the piston head during the power stroke, known as increased BMEP or brake mean effective pressure. With a given bore and stroke this increases the developed horsepower and torque. Otherwise one needs to increase both to give a much larger displacement and thus a larger and heavier engine and that is not desired. One may also drastically increase the speed with which the engine operates; but this is not desired from a wear and noise standpoint. One of the great charms of the steam powered car is the silence obtained when it is going about its tasks. “With the alacrity of a big yacht leaving it’s moorings”, said the Doble publicity.

The historical steam car engines ran between about 400 psi and 1200 psi while the Cyclone uses up to 3,200 psi, termed super critical. This increased the power density of the engine as regards horsepower per pound and per cubic foot of overall size to the desired level. The desired criteria is the highest practical drop in pressure between the inlet valve opening and the exhaust port venting the steam.

Increased Net Cycle Efficiency. This is accomplished by increasing the temperature of the steam entering the engine or expander. The highest practical inlet steam temperature vs. the lowest practical exhaust temperature. It provides a means of increasing the expansion ratio per stoke of the piston. This is aided by employing the unaflow system where the inlet valve is in the head of the cylinder and the exhaust is vented by ports at the bottom of the piston’s stroke. Thus the inlet head end is kept hot by not pushing colder exhaust steam out the same port used for inlet steam and the exhaust end is kept cool and not reheated by the hotter incoming steam. One also pays strict attention to employing only the shortest possible ports from the inlet valve to the cylinder and keeping them straight, short and as smooth as possible. Turbulent flow is to be avoided, the lowest possible flow losses in the porting. In the best practice, the inlet valve opens directly into the cylinder with no intercommunicating port at all. This also includes using the highest practical compression ratio and thus a minimum clearance volume.

The old steam car engines were limited by the need to inject special cylinder oil to lubricate the piston rings and valves and this put a cap on how high one could superheat the steam. Exceed this temperature and the oil became carbonized and caused very high maintenance demands in keeping the steam generator coils clean, the condenser washed out at frequent intervals and draining this accumulated oil from the water tank. This carbon also caused rapid piston ring wear.

With special piston ring materials and specific points of injection onto these rings, the Cyclone engine is able to use the operating fluid, water, as the lubricate for these rings and also for the special crankshaft bearings. Eliminating cylinder oil was and is a most major advance in the technology.

The old oils were limited to around 650°F-700°F maximum, putting a definite cap on the ultimate cycle net efficiency. Eliminating them and using water, the Cyclone is able to use steam temperatures up to 1400°F, the highest possible and usable working temperature today with most modern metals.

One other feature is employed with good effect in raising the net cycle efficiency. Paying close attention to heat losses with improved insulation and heat barriers and using high efficiency heat exchangers to return otherwise wasted heat back into the cycle has proved to be very beneficial.

Mechanical Features. The best efficiency of a Rankine Cycle engine occurs with the before mentioned high expansion ratio in the cylinder. There are limits to this, however. An ultra short admission phase causes a lumpy torque curve and a rough running engine at slow speeds. Increasing the number of cylinders and being realistic with how short the cutoff is diminishes this effect. However, this ultra short cutoff is only used when the engine is running at high speed. At startup, at slow speed and high effort the cutoff is lengthened to give smooth running by use of the variable inlet valve timing.

It also assists the improved efficiency when the dead space at top dead center of the piston stroke, termed the clearance volume, is at an absolute minimum, a high compression ratio.

It occurs too when the inevitable residual steam left in the cylinder after the exhaust ports close

is compressed to a point where the compression temperature caused by the high compression ratio is equal to the temperature of the incoming steam when the intake valve opens. The incoming steam then does not lose temperature and waste heat by having to heat up the cylinder head, intake porting and piston head. As this varies with the working pressure inside the cylinder by use of the throttle, an automatic pressure operated relief valve between the cylinder and the intake manifold must be used. This automatically balances this compression pressure to match the incoming pressure under all load conditions. A seldom understood feature used by the Williams Brothers in their engines during the Clean Air Car work, although first described by Prof. Stumpf in his book on the unaflow engine in the 1922 edition of this pivotal book. The complete bible when designing unaflow engines.

A final advance over the historical steam car engines of the past is to stay with the single acting engine and not use the double acting. The large reduction in both weight and size, plus the ability to run at much higher speeds dictates that this is the best way to design the engine. Carrying this one step further, the two crankshaft opposed piston design has the best possible advantages over the usual engine layout for many reasons. A separate subject for discussion and outside the scope of this paper.

Weight Reduction. The use of multi parallel circuits in parts of the steam generator in place one long single tube can increase the heat transfer rate and thus the production of steam per square foot of heating surface. However, the designer must take great care with the control system and water feed to each coil so that tube burnout due to water starvation or surging does not occur in any one circuit.

Extended surface steam generator tubing with fins will also greatly increase the evaporation rate per square foot of heating surface and per linear foot of the tubing in the steam generator.

The control difficulties of such steam generators are not usually well understood by modern steam car developers. Tube burnout and surging are common failure modes. A most satisfactory solution is to use the Lamont style steam generator in preference to the Doble system. This use neatly side steps all the control problems of the monotube steam generator and provides a great improvement in the amount of steam produced per hour from each square foot of heating surface, plus a good reduction in weight and size of the unit and it also enhances the safety factor.

The worldwide intent to reduce climate change and the recent US government fuel and mileage mandates has had a major impact on the American automobile industry. Couple this with the ongoing financial problems the industry is undergoing right now and a rational vehicle power source is a subject that must be reviewed with concern and dispatch. The various approaches to improving the gasoline engine are nearing the practical limit, there is just so much one can do with that engine or reliability is going to suffer and high and frequent maintenance and repair costs will be seen.

Under their present financial stress, the Detroit auto industry is reaching for solutions they can implement immediately and satisfy the various Governments politically driven objectives. Solutions like hybrids of all types and much smaller engines are designs that can be brought to market with modest investment in a short time, as their technology already exists. With the mandates by Congress calling for drastic improvement in mileage standards as the panacea, they have little choice but their present course of compliance. Then, what if the consumers reject the cars and you cannot sell them?

The entire world automotive community realizes that the standards and mandates implemented by Congress, the E.P.A. and the Calif. Air Resources Board are politically driven, severely lacking in practicality at times and are often simply not realistic or cost effective. They are not optimum by any means. Political goals often override the science and engineering in these mandates and rulings and management reluctance to confront Government with a consolidated front is well known. They will not take an aggressive collective stand to ignore or demand modification of these mandates. Then consider that by the time these recent mandates are to be in use, there will probably be at least two new administrations in office in Washington and things may be changed again.

Politicians promote fuels such as compressed natural gas and alcohol that continue to produce CO2, while stating that their intention is to reduce the emission of this gas into the atmosphere.

Hydrogen is embraced by politicians and paid EPA and CARB advisors for the naïve reason that it emits only water vapor in the exhaust when used with IC engines. What appears to be deliberately suppressed is the knowledge of the huge amount of energy it takes to make hydrogen and the fact that today there is no national distribution network.

What would also be of concern is the storage of hydrogen in the vehicle. Liquid hydrogen is the form with the highest energy density per pound; but as it is in this state only when maintained at

-423.7°F, one experiences boil off to prevent dangerous pressure buildup in the storage tank. Unlike propane, hydrogen at least rises upwards and does not collect on the garage floor, just waiting to accumulate next to the burning water heater pilot light. Hydrogen has a high flame speed and is very easily ignited. The home insurance companies may have some deep concerns here.

It also diffuses through some metals and a high pressure leak will auto-ignite just from the friction of the gas escaping through the leak point.

The IC engine uses hydrogen in gaseous form and it has a very low energy density, only 319 BTU per cubic foot. This says that a high consumption rate is in order and the vehicle will have a short range similar to battery electric cars. Hydrogen is too unsatisfactory to continue promoting the use in vehicles.

It is amusing to see that the various Government agencies and environmentalists promote alcohol fuel as if it was the latest discovery. When in fact it was used in the very beginning of the 20th century for automobiles. There were even pre WW-1 endurance events in Europe where alcohol was the only fuel allowed. Even back then, they were having an oil crisis. It has been used in racing cars ever since those days. There is nothing new in using alcohol in an IC engine. Just as there is nothing new in using vegetable oils in the Diesel engine. Dr. Diesel proposed and did this with his very first test engines before the turn of the century using peanut oil.

The fuel alcohols are very hydroscopic, absorbing water from the atmosphere. This accelerates corrosion in various automotive components and also in pipelines, the reason why alcohol has to be transported at present in trucks and not interstate pipelines. It is also a serious source of dilution of the engine’s lubricating oil. Excessive piston ring wear is expected with direct fuel injection engines.

E-85 will be a serious problem in older cars should it become the mandated fuel for IC engines.

Alcohol is a fine fuel for racing cars and has been for over a hundred years; but it is not satisfactory in any regard for passenger cars.

There is also the situation that the corn feed stock promoted by the Government with farm tax subsidies for growing it is causing serious damage in the Gulf of Mexico. To be a profitable crop, corn requires a large amount of nitrogen fertilizer and water. The runoff from farms in the Mississippi River Valley has polluted the seabed around the mouth of the river to the extent that has caused the die-off of the algae growth and subsequent death of the bottom dwelling species sufficient to ruin the inshore fishing industry. The fishermen have to go far out into the Gulf for their catch and this has raised the price of seafood in the market.

However, the recent massive crude oil disaster in the Gulf has rendered this older pollution problem redundant. The immense amount of damage this oil spill is causing far overshadows any previous spill. This is the world’s most major oil spill and the ramifications are going to be felt for decades.

The engineering for the Rankine cycle engine is different and complex and embraces many disciplines besides pure mechanical engineering. Fluid flow, aerodynamics, thermodynamics, heat flow, combustion technology, all need to be interwoven into this one area of engineering. It is made even more difficult by the fact that most of the advanced knowledge is in private hands and simply not available for general or even corporate study. There is also the situation that engineering schools do not really teach Rankine cycle technology any more. A cursory once over is all it gets today and only that as applied to large industrial use such as power plants. Even marine use is supplanted now by the Diesel engine.

Experiences in this field of engineering with the early Government funded Clean Air Car and Steam Bus programs exposed the errors in the naive thinking that occurred then. Impossibly limited development time and deliberate under funding were a few of the prime reasons this earlier car program failed to live up to expectations. The bus program was marginally better. Coupled with the fact that most of the involved development firms did not have one bit of real hands on experience with any steam car, antique or modern. Only a few possessed some limited knowledge, mostly wrong.

It had to work perfectly almost right off the drawing board was the expected timetable. Funding was deliberately short as the firms were expected to contribute to the effort, with the implied idea that future production profits would make up for the expenditure. This never was part of the program, although several developers had convinced themselves that it was to be the second phase of the entire program. Along with some developers who were really in the government grant harvesting business and not the steam car business to begin with. Right from the beginning the Clean Air Car program was doomed to failure.

The large number of backyard inventors and promoters did not help the situation one bit. They got into print with some of the most outlandish proposals that violated every law of engineering and thermodynamics known. The term “Steam Nuts” became almost universal thanks to this.

Government sham was also involved. California State Senator Nicholas C. Petris of Oakland, managed to get a bill passed that supposedly would reward the developer of a clean air car the sum of $25M. The bill passed, the allocation of one cent did not. Making this one more comic opera of a grandstanding buffoon politician using the program for personal publicity. There were others too.

Past experiences with Government agencies has convinced many accomplished developers that such alliances are not productive or rewarding and they avoid any such entanglement. The previous attempts have proven the worthlessness of such Government involvement and attempts at generating any meaningful progress. Many efforts were organized then and all failed for many reasons. All of these failures to produce a worthy and fuel efficient modern steam car have left a legacy of total rejection by all the automotive companies, today a very hard barrier to overcome.

One must acknowledge the economy for the motorist today in driving a Diesel powered vehicle. An engine notorious for long life with minimal service demands, with high torque output and better fuel mileage than any spark ignited IC engine. It is reported that about 70% of European new car sales are now Diesel powered. Their tax structure for Diesel fuel is much more realistic than that applied here in this country.

However, this engine has an inherent serious NOx problem. Recent developments by Daimler-Benz, BMW, VW and others in Europe and primarily Honda in Japan have at least put this gas under some control; but at a furious cost for the exhaust system. Future work will provide a more cost effective solution than the present urea injection system now used. At least urea can by synthesized and not obtained from the obvious source that comes instantly to mind.

What is most interesting is the fact that the latest Honda and VW Diesel cars do not use urea injection. They have developed an exhaust system that uses other means to reduce the NOx emissions.

Encouraging the wider use of the automotive Diesel engine and the ready availability of pure bio fuel oils from carbon neutral plants and algae should be the focus right now and not alcohol or hydrogen. Such a combination will satisfy the environmental concerns, give high mileage to home produced fuels and supply the average motorist with a most satisfactory engine. An engine that is already seeing high production volume in Europe. Not the promotion of various concocted hybrids, like the Chevy Volt and other science fiction solutions. The Volt hype one sees coming out of General Motors is amusing, to say the least. OK, 40 miles on just the battery power and then another 200 miles on the gasoline engine. So now what are you supposed to do in the middle of the night in Snake Navel, Wyoming? The Volt is certainly not the responsible size of vehicle for city use, something more like the BMW Mini electric or the proposed Ford Focus battery electric is much more practical.

When and if a satisfactory and reliable Rankine cycle engine is available and publicly demonstrated, it can be offered with confidence to the automobile industry as an alternate to the Diesel engine. Until that time, only the Diesel is considered to be satisfactory for the automobile. With the battery electric perhaps usable as a purely city car; but only when a drastic reduction in cost of the battery pack is seen by the market and sufficient generating and distribution capacity is in place.

By mandating a large reduction in the use of fuels in the automobile, the Federal Government is not acknowledging the operational problems that such a reduction will cause the average car buyer. The latest concept to also drastically reduce the fuel consumption by large Diesel interstate trucks is causing considerable worry, for there is no satisfactory alternate power source for them. A fact that the present Government seems to be ignoring in it’s liberal quest for instant utopia.

The immediate response by Detroit is to propose small displacement, highly turbocharged engines that will meet the requirements with hybrid systems tacked on. Such engines are heavily stressed and the possibility of high maintenance costs to the car owners is a definite probability. The apt term used for these engines is “grenade engine”. To date (2010) it is not known as fact if any automotive company has sat down and done an honest and all encompassing total engineering appraisal of ALL the power systems available to them. This presumes that they are really in possession of all the facts and data for each power source. It appears that this has not been done in any dispassionate form by anyone. The solutions to the Government mandates has been to grasp the easiest system known to them that will satisfy the mandate and let it go at that. Modern corporate management avoids technical risk at any cost.

The position taken in this paper is that actual mileage alone is only one part of the solution. Where this fuel comes from, the reduction of CO2 and if the nation continues to rely on foreign oil are also subjects that must be competently reviewed and serious improvements implemented. A reasonable and rational total and long duration solution is urgently needed. Not a panic driven grasping of power systems ideas which are more science fiction dreaming than realistic.

Multiple bicycle pedals under the seats of a public bus would be amusing, albeit a bit smelly in the summer and actually work, but hardly practical. Various “Green” TV programs even gave this idea airtime as a serious proposal. Compressed air is another rather absurd proposal also given exposure on several of these environmental science TV programs that should know better. The entrepreneur proposing this misguided and foolish idea as “Free Energy” described the car as being equipped with a compressor to replace the air used by the engine as the vehicle moved down the road. The “Nearest thing to Perpetual Motion” the gushing and ignorant announcer was saying. A violation of the Second Law of Thermodynamics if there ever was one.

Home produced fuels (alcohol and bio fuel oils) are solutions; but are coupled to the specific engines these fuels can be used with successfully. Failure due to lack of funding or basic knowledge and a lack of competence in making fuel oils from food waste will damage the Diesel engine in a big way. Also price gouging is not encouraging the use of properly produced bio fuel. Presenting a five page disclaimer one has to sign at the fueling station stating that they are not responsible for any engine damage most certainly does not inspire confidence on how or where that particular station got the fuel, a proper commercial refiner or someone’s back yard?

CO2 is still produced when burning some fuels such as alcohol, as it contains hydrogen and carbon in the molecule. Some fuels cannot be used with the spark ignited IC engine and the most cost effective bio fuel oils are only usable in the Diesel engine or the Rankine cycle engine. That fuel is carbon neutral and that one parameter is more important than the actual mileage obtained that the Government now demands. Pure bio fuel oils and the Cyclone engine, or some other highly advanced Rankine cycle engine, are viewed as long-range successful potential candidates.

WHY CONSIDER THE STEAM ENGINE FOR AUTOMOTIVE USE.

The reciprocating positive displacement steam engine and the electric motor are the only two power sources that correctly match the torque/speed load requirements of the automobile. The automobile requires full and high starting torque and only both of these power sources provide this condition.

The electric car is now receiving serious attention, large publicity, financing and some production, the Rankine cycle powered vehicle is not. The electric car carries a finite supply of electricity in the form of chemical energy in the battery. The Rankine cycle steam engine has a continuous supply of energy as long as fuel is supplied to the burner.

The electric car success mainly depends on the new Li-ion polymer batteries for energy storage. They are presently very expensive, however rapid advances are being seen in mass production of these storage cells for automotive use. If it is sufficient is the question. There are other aspects of electric car propulsion that are yet to be solved. The charging power source enlargement, the fire danger of using an alkali metal, disposal of spent cells, cooling requirements of these batteries and the environmental needs of the utility power plant increases that would be required if such vehicles were really in mass production and widely used. Disposing of the increased production of CO2 from the added power plants would be a major concern. Sequestering carbon in rock strata is a poor temporary solution. A better one is to not produce it at all by using carbon neutral fuel.

The bulk of electrical power is still generated by burning coal or natural gas in the United States.

Solar, wind and geothermal are as yet too small a scale. These are now receiving great attention.

The environmentalists want hydroelectric dams destroyed so the fish have an easy time reaching their spawning grounds. Which is more important, keeping one’s lights on or sex for the fish?

However, the battery electric car is not pollution free as many developers claim, like the TESLA firm. The vehicle, yes, the power source definitely not. It has only been moved many miles away; but it still produces pollution that must be controlled. It is also not an efficient vehicle power source when considering the pound of fuel burned in the power plant, as compared to the actual power delivered to the rear wheels of the electric vehicle. There are many losses en route.

There is one pending problem that would become very serious if electric cars were to be adopted in really large numbers for city use. The nation’s power grids are already in trouble and many have seen brownouts and blackouts when the grids are simply overloaded in the summer. This problem is already recognized and utility companies are planning enlargement of the grid networks. However, the advances in electric car development and their increased sales are not yet actually being matched by equally rapid construction of the new transmission grids and associated power plants.

Many, accompanied by howling dissention by environmental groups, suggest increasing the number of nuclear plants. A most suitable power source along with greatly expanded solar and geothermal. Many learned studies suggest that efficient hot gas closed Brayton cycle turbine generators replace the present breeder reactors and steam turbines with pebble bed reactors as the much safer nuclear heat source. These do not generate radioactive waste products like the present nuclear reactors do.

Many futurists and environmentalists champion the use of fuel cells with hydrogen as the primary fuel. The entire energy consumption and cost to produce and use this source is high and there is no nation wide distribution network to supply the hydrogen. There are serious storage problems with vehicle hydrogen systems and there are operational problems and safety issues that would need considerable investment to overcome, if ever possible. Fuel cells do work and they show high conversion efficiency and are very useful in stationary applications. Cost and the entire system acceptability are matters yet to be resolved when using them in vehicles.

Demonstration fuel cell vehicles are good publicity and show technical competence; but not practical everyday use for the consumer at this time. They also do not like extreme heat or cold or vibration. It may also occur that manufacturers may see that fuel cells and their associated support hardware in vehicles are just too complex and expensive to continue supporting.

A two million dollar Toyota, BMW or Mercedes-Benz fuel cell car certainly shows technical expertise and impresses the naïve politicians; but is light years away from being a fixture in anyone’s garage. Basing any new power source for the automobile is easier and cost effective when existing fuel distribution networks are used and some existing hardware can be converted to use.

Compressed or liquefied natural gas, hydrogen, hybrids, fuel cells, plug-in-hybrids, alcohol and various combined systems are not long-range solutions, only immediate palliatives. Some of these fuels still produce CO2 in their production and use and that fact cannot be ignored.

ENGINE CHARACTERISTICS AND COMPARISONS.

The immediate consideration is just what automotive power source could satisfy all the needs and then is it really practical, reliable and cost effective and satisfactory for the average motorist. The other main consideration is whether a new engine can quickly be put into production, even on a limited basis. What tooling costs are involved and what training of the assembly line workers is needed? How would it affect the suppliers? What would it cost to effect even a limited conversion plan?

One other consideration is whether any automobile company will even look at such a new engine. The cost and time factor plus the ingrained corporate negative mind set against any such new power source may take Government action to overcome. Not just the actual car manufacturer; but also consider the vast number of subsidiary component supply companies involved. A major tax break perhaps or some really meaningful incentive for the purchaser?

One major thermodynamic loss is present in the Rankine cycle engine that is unavoidable, the loss from the heat of vaporization of water. This means adding 947 BTU/lb just to effect the phase change from liquid to gas, then rejecting that heat to the atmosphere in the condenser where the exhaust steam is changed back again into water. This process is done with none of this energy used for the production of power and it is a total loss. For the competent engineer, this means more than just average attention must be paid to minimizing any other heat, fluid flow and friction losses in the system and also the most efficient expander possible must be selected for use. The various heat exchangers and their thermal efficiency are of critical importance to such an engine.

The spark ignited IC engine and the Diesel engine are not self-starting from rest. They require some outside power source to put them into operation, the electric starter. Both demand that when the vehicle is stopped or waiting in traffic some means of disconnecting the engine from the load is needed. Either a manual clutch or the torque converter in a vehicle with an automatic transmission is the common means of accomplishing this.

The torque and horsepower output of either engine is at minimum when only idling, so a multi-speed transmission is mandatory. This is provided now in almost every vehicle by a costly computer controlled six or seven speed automatic transmission. In vivid contrast, the steam engine produces maximum starting torque when the high pressure steam is first admitted to the engine. Thus the starting torque is highest when first starting out and it often is a massive amount. Even with the vintage steam cars of yesterday, this torque can and did amount to over 2,000 lb/ft. making the acceleration of such a vehicle extremely dramatic and very exciting for the driver and passenger with almost effortless total silence, one of the most attractive characteristics of a vehicle steam power plant. To put things as simply as possible, brute torque is acceleration while horsepower is speed.

Torque can be varied in the steam engine by a wide amount by use of variable inlet valve timing, described as “cutoff” control in steam engine parlance. Varying the duration of how long the incoming steam is being admitted to the cylinder per stroke changes the expansion ratio in the cylinder. This provides this engine with massive starting torque when demanded for acceleration or hill climbing with longer admission timing, long cutoff. Using short cutoff and thus larger expansion of the steam in the cylinder when cruising along on the highway gives the maximum economy of steam use. Long cutoff uses more steam than short cutoff; but this is commonly only a short duration event.

The result is that in most steamers, no transmission is required, although a two-speed transmission with a neutral position has been shown to be a very large advantage. As with the old White steamers two speed rear axle, you didn’t have to use it to get going; but under some difficult situations like deep sand or mud then it proved to be one of their best ideas. Today it is most useful in city driving and particularly if hills are also encountered, as in San Francisco. Reversing the engine is accomplished by changing the valve timing 180° and this means that no special reverse gearing is needed as the engine reverses itself. This provides a very major cost saving over any IC engine for vehicle use.

The prime goal of the responsible scientific community is to reduce as much as possible the CO2 level produced by industry and the automobile, making any carbon neutral fuel commercially and morally attractive. It is also charged with seeing that the total energy consumed by any new fuel system being adopted is as low as is practical. The secondary goal is the use of homegrown fuels and to not depend on foreign oil as the base fuel material. Basing one’s fuel supply future on unstable and often unfriendly nations is a risky business. Alcohol and fuel oils from plant material and algae are the two receiving the highest attention. Alcohol is not carbon free, while plant and algae fuel oil is carbon neutral. The reduction of the exponential speed of climate change is the primary emphasis for all of this work.

There is one feature of the Rankine cycle engine regarding fuel consumption that is very beneficial. When the vehicle is in town use residual heat does the main job of maintaining the steam conditions. When just puttering along the burner is off most of the time only coming on for brief periods to maintain steam pressure and temperature. In city traffic the Rankine cycle engine enjoys better fuel mileage than when on the highway where the burner is on primarily all the time. With city driving the IC engine must consume fuel to keep running continuously so as to remain in operation.

However, in the steamer this means that the essential powered auxiliaries, the power steering pump and the power brake vacuum pump, must be driven by some alternate source such as an electric motor when the vehicle is stopped. Normally they are run off the main engine. The battery can substitute for the alternator for these brief periods. It would be helpful if the electrical system were 24 volt or the proposed 42 or 48 volt now being considered.

There is ample precedent to using a separately steam driven auxiliary unit for these purposes. These needs require some very careful consideration and a competent energy balance study to make the decision. The past history of steam cars has well illustrated the fact that some separate engine best drove the ancillary loads then. This decision requires serious thought now, as the type and operating characteristics of the steam generator have a big influence on how the auxiliaries are powered.

This is not a simple problem and it demands some very careful and skilled analysis to be correct.

The Rankine cycle engine is external combustion the IC engine is internal in the cylinders. The constantly varying temperatures and pressures in the IC engine greatly influence the actual combustion process. In the Rankine cycle engine combustion is at a constant low pressure and continuous. When properly designed, the burner provides the very best possible pollution control over any fuel burning IC engine with absolutely no pollution control hardware needed. Another cost saving over the gasoline and Diesel engine, as the need for the present computer controlled systems for engine management, valve timing, automatic transmission management, ignition and fuel injection requirements, all vanish in the steam car. It requires none of this hardware or electronic controls.

This very clean burning condition is accomplished in several ways. The combustion air pressure in the firebox is less than one pound per square inch and the fuel particle has a long residence time in the burner, combustion is a continuous process, insuring totally complete clean combustion. If the combustion temperature is held down below 2300°F by means of secondary air admission to the firebox, then NOx is not produced. This does not harm the cycle efficiency. To date, net reproducible cycle efficiency of the Cyclone engine is 28%, with 32% in the immediate future. Already making this Rankine cycle engine competitive to the vehicle gasoline engine. The best Diesel engines showed about 35-38% and that is hard to beat. However, this number is suspect as nothing was reported if it included the automatic transmission losses or not. If an automatic transmission is part of the system, then the Cyclone is an even match.

In dynamometer testing already done with calibrated instrumentation, the Cyclone shows no CO, no unburned hydrocarbons, NOx is virtually immeasurable and CO2 is neutral when pure bio fuel oils are used. The burner of the Cyclone engine can use any light liquid fuel that can be supplied to the fuel pump. Alcohol, gasoline, Diesel oils, kerosene, vegetable oils, or particularly the pure bio fuel oil now being produced from plant waste or algae are all usable fuels. This is done with no special added on control systems or modifications to the burner fuel delivery system or to the combustion chamber.

This is simplicity personified when compared to any vehicle IC engine today. A major cost savings.

This reduction in CO2 production must be compared to the IC engine burning gasoline, or a gasoline-alcohol mix like E-85. Fermenting various cellulose materials with enzymes produces the alcohol. The process generates large amounts of CO2. The IC engine burning gasoline or alcohol produces CO2 in the exhaust. Unavoidable, as carbon and hydrogen are the component molecules that make up alcohol and gasoline.

Natural gas is also composed of carbon and hydrogen called methane and it too produces CO2 when burned in the IC engine. Another gas whose harmful effects on global warming are seemingly suppressed in the media. This gas is 25 times more harmful than CO2. Methane is a naturally produced gas and man cannot eliminate or really control methane emission from natural sources. Should global warming continue, the methane hydrate ice deposits at the bottom of most oceans would be released with a devastating effect on the earth, another good reason to suppress this global warming.

The energy content of alcohol per pound is less than gasoline or Diesel oil. Alcohols are around 8,500 BTU/lb. while the petroleum fuels and pure bio fuel oils range around 19,300 BTU/lb. To obtain the identical power output from the same engine when burning alcohol one must increase the fuel flow rate. It is also advantageous to increase the compression ratio to take advantage of the high octane rating present in alcohol. If done, this results in engines that then cannot be fueled by burning gasoline again as destructive detonation takes place with fatal piston damage occurring.

The vapor pressure of alcohol will cause hard starting problems in cold weather. Burning alcohol in the IC engine with its changing internal pressures and temperatures also produces some dangerous byproducts that are health hazards, because of government mandated additives to the base alcohol. This is presently done to ethyl alcohol by adding formaldehyde to prevent human consumption. Methyl alcohol brings along even more pollution concerns and a more serious corrosion problem.

One important restriction present is that the Diesel engine cannot use alcohol fuel and the spark ignited IC engine cannot use these bio fuel oils. What is desired is an engine than can cleanly use any liquid fuel without any compromise. The selections available just got very small, microscopic in fact. Only the Rankine cycle steam engine, the Stirling cycle hot air engine and the Brayton cycle gas turbine satisfy this condition. The gas turbine is ruled out due to high fuel consumption, particularly at part load, along with high production costs and extreme operating temperatures if any reasonable efficiency is to be seen. The Stirling is also very expensive and is most difficult to throttle and is large for the power production a specific engine will produce. Ford tried it in vehicles and gave it up.

The Diesel engine when burning this bio fuel oil also shows a neutral carbon emission condition and a high net efficiency. However, as the Diesel cycle depends on a high compression ratio for the ignition phase and a resulting high combustion temperature, the NOx generation is a very serious matter. NOx is inherent with any Diesel cycle engine and unavoidable, as is the production of soot.

Soot is a result of momentary imbalance in the air/fuel ratio. Reports and experience have identified the universal use of turbo-charging with the Diesel engine and one particular transition point that is the root cause of the soot production. Open the throttle quickly and the fuel flow rate is immediately increased; but the turbocharger has not spooled up to the point where the excess air is produced. Some form of interlock is indicated. This condition causes an over rich mixture and soot is the result, the belch of black smoke when an older big truck takes off from a stop. Manufacturers are now including variable turbine inlet vane turbochargers and two stage supercharging in an effort to maintain the right air/fuel ratio at all speeds and loads with a mechanical supercharger and a turbocharger in series. Or smaller twin turbochargers that spool up faster. Plus the inevitable present panacea that all manufacturers turn to in desperation, digital electronic fuel injection management.

Some industrial Diesel engine manufacturers have stopped supplying these engines for truck use, as the cost of efficient NOx and soot pollution control devices has driven the cost of these engines beyond what their customers will accept. Caterpillar is one who took this path in 2008.

Automotive users of the new Diesel engines, while very good with fuel consumption, very durable and giving a high torque output, are using involved, expensive and complicated exhaust converter systems to meet the EPA pollution standards. These require the addition of special fluids and reactors to the exhaust stream to control the NOx and converters and filters to handle the soot production. This addition and some intrusive mandates from the EPA to insure that this fluid system always operates, have added unnecessary high cost to the new vehicles that offer Diesel alternatives to the usual gasoline engine. Their new common rail fuel injection systems are computer controlled, adding more cost and potential reliability problems that are already being noted. Automotive computer electronics are not made to combat mill specs, as are the ones for military aircraft, they are made as cheaply as possible to keep the price down. Some data suggests that all the usual new large interstate truck Diesel engines now require such a pollution control addition to meet near term government mandates and that the cost is up to $14,000.00 per engine (Cummins). This is simply not acceptable to truck owners.

A mandate by the Port of Oakland that all Diesel trucks that service the docks must be equipped with NOx and soot elimination exhaust systems on Jan. 1, 2010 resulted in an interesting situation. The independent truck owners and the fleet operators said that they would shut down the Port unless the Port Authority came up with a solution, abandon the mandate, or provide the financing for these new exhaust systems, at a cost reported of now $25,000.00 per truck. The first test systems also uncovered the need for frequent cleaning of these new exhaust systems at a substantial cost that further angered the independent and fleet truck owners. This is yet an unresolved situation.

As this is a strong union, the Seattle and Long Beach ports would also support the strike. The Oakland Port Authority “discovered” $14M to buy the exhaust systems and extended the deadline to May 1, 2010. At which time if they do not fund the systems, then the truck owners vow they will shut down the Port. As reported on all TV news broad casts locally. Commerce cannot allow these ports to be totally shut down. The resolution to all of this has not been noted in the press as yet.

A new power source for them is needed. The large truck and bus industry may be more receptive to a new engine than the carmakers. For them, with their high horsepower and reliability demands, the Band-Aid/science fiction approaches that the passenger vehicle manufacturers are taking are not responsible solutions and as some reports indicate, are not accepted.

One inspection under the hood of any new IC automobile will amply illustrate just how complex and costly all this pollution control and engine management has driven matters. For the long term vehicle owner, all this hardware and electronics translates into some eye watering repair bills down the line. An alternate engine for them is also indicated and the Cyclone neatly bypasses all of this.

It is also noted that these government agencies are now giving attention to mandating a similar requirement with marine Diesels, railroads, farm and industrial engines and even down to lawnmower sized engines. It appears that any Diesel engine is going to be involved in this.

What is still a present viewpoint by the entire automotive industry, is that the Rankine cycle system was such a miserable failure during that Clean Air Car program the government sponsored between 1960 and 1985, that they refuse to even give it one glance today as a potential candidate. As one very senior executive told the author at dinner: “We all watched it with great care and interest; but with that total failure, as far as we are concerned the steam car does not exist.” They constantly bring up the poor fuel mileage of the vintage steam cars. Which in truth were not all that bad when compared to the gas engined vehicles of those days and kerosene was much cheaper than gasoline. To date, the Rankine cycle engine is completely dismissed from any consideration.

What is needed here and soon is a nice installation of a Cyclone engine in a modern automobile and for it to be exhibited and demonstrated. If it really is shown to be as successful as it should be, then these previously held viewpoints could be erased. This has not been done to date.

What is sadly noted is that not one suitable Rankine cycle system is even known that could satisfy this need, except for the Cyclone engine and it is still in the late development stage. What has still to be proven with the Cyclone engine is the long term durability and operational excellence. Extensive dynamometer endurance testing will answer this one question, as will lengthy operation in an actual vehicle answer the second. No other company has chosen to seriously investigate, develop and research the advanced steam power system and fund the operating prototypes.

As far as the introduction of a new and good steam car is concerned, much depends on the timing of that introduction. The battery electric is getting major investment and continuous good publicity. The steamer is being pushed further and further into oblivion by this media attention to the electric car, in fact it is totally ignored by one and all. Unless this introduction occurs rather soon, the steam car will have an almost impossible hurdle to overcome. It could occur that even a high end GT vehicle will not see any support and financial assistance. Only the large interstate truck like the Peterbilt or Kenworth may then be the only vehicle application seen.

The historical version of the automotive steam system has always been a collection of components all tied together by a maze of plumbing and fittings. The Cyclone was designed from the start as an integrated one-piece unit of impressive compactness. The photograph at the end of this paper shows the current developed automotive Cyclone engine for automobiles. Every single component that makes up this Rankine cycle engine is packaged into one neat unit and it will easily fit where the present IC engine is located in the vehicle. The Company has various sized models to choose from.

The only outside connections are the fuel line, the cable supplying electric power to the combustion air blowers, plus the forward-reverse lever and the output shaft.

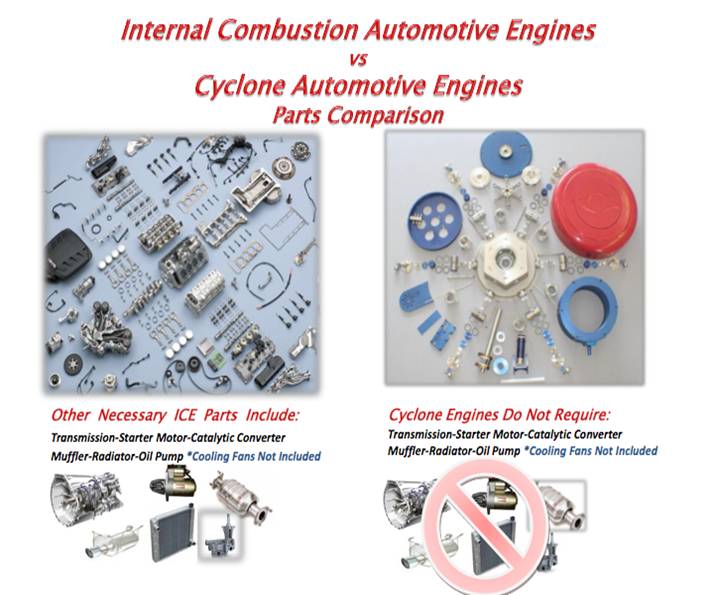

The moving parts count in the Cyclone engine is drastically reduced when compared to any IC powered vehicle. Compared to the present automotive IC engine and automatic transmission, the Cyclone is simplicity personified, as the picture at the end of this paper well illustrates.

The control of the steam pressure and steam temperature has been a vexing problem with some earlier steam car systems. Early addition of electric controls to the Doble and other steam cars in the 1920’s only managed to add some unreliability issues. The Cyclone engine is able to employ simple relay logic controls fed by thermocouples and a pressure switch to control the water feed and burner operation, or the simplest of microprocessor control modules.

The cost savings here with this engine are a major improvement over the highly complex computer systems now employed with the IC gasoline engine in vehicles for engine, transmission and fuel injection management. The noted cost savings over any hybrid, plug-in-hybrid or other such pasted on additions to the gasoline engine are going to be a major savings in the production costs over those vehicles.

There is one additional potential issue with employing any steam system for vehicle use, the labor time to assemble the engine. In point of fact, there is just a lot of plumbing to screw together and be sure it is leak proof. However, every single major automotive company makes special high performance models in limited production. Mercedes-Benz has their AMG division, GM makes higher performance Corvettes, Chrysler makes the Viper, Porsche has many models of the same car and on and on. They are already used to small scale production runs of special cars. This situation is not considered to be any kind of hindrance with the Cyclone engine.

The tasks to assemble the Cyclone engine are not involved, only different and there is no logic to consider that producing such an engine would cost even as much as these high performance special cars. This is not seen as a problem for even limited production. Careful analysis of the complete Cyclone engine indicates that it will be less expensive to produce than the present high performance limited production cars, not to forget that it completely eliminates the complicated and expensive automatic transmissions and support electronics now in universal use.

There is one other previous operating demand with the old steam cars that not only limited the cycle net efficiency; but also added frequent and involved maintenance demands that could not be ignored. These centered on the need to inject special steam cylinder oil into the steam line to the engine to lubricate the piston rings and valves. This oil contaminated the heating surfaces in the steam generator forming carbon that had to be cleaned out on a frequent basis. It also coated the steam side surfaces in the condenser and reduced the heat transfer rate by a considerable margin. It also limited the maximum steam temperature that could be used to about 650°F-750°F, the thermal breakdown point of the oil and this put a cap on the net cycle efficiency. Any failure of the oil injection pump and instant engine destruction was and is often seen.

From the start of the development of the Cyclone engine this oil need was identified as harmful and rejected in toto. The Cyclone is a totally water lubricated system, the working fluid itself. The specially developed crankshaft and connecting rod bearings and the piston rings use only the deionized or distilled water that the engine cycle uses. This enabled the company to work with much higher steam temperature and this made a drastic increase in the net cycle efficiency of the Cyclone engine.

This is simply the most dramatic and major improvement in the Rankine cycle engine seen in the past sixty years. The Cyclone engine is showing durability and this development has well proven its worth. Of course material research was needed to accomplish this feat; but it was done successfully. This was the most critical, important and pivotal development by Cyclone Power Technologies Inc. Without this oil elimination, the Cyclone engine would never have gone beyond the efficiency of previous steam car power systems.

Two operating conditions are employed in the Cyclone to make this Rankine cycle steam engine competitive to the gasoline or Diesel engine, as mentioned earlier; but they need to be emphasized again for clarity. Very major increases in the power density and improved higher net cycle efficiency were absolutely essential, along with much improved packaging of the power plant.

Power density was gained when the operating pressure was increased for the same engine. The Cyclone uses steam at up to 3200 psi. Coupled with this are the use of very low clearance volumes and a very short admission cutoff at speed. The combination has proved to be very successful. The efficiency gain is obtained by increasing the steam temperature from 500°F-750°F up to 1200-1400°F. They are known together as a critical or supercritical cycle.

The Cyclone is also shown to gain a higher net cycle efficiency by the use of carefully designed heat exchangers that recover waste heat in the cycle and recuperate that heat back into the cycle where appropriate. This was definitely one of the major sources of loss in the old steam cars.

There is a materials limit to how high one may go with steam temperature, so careful attention to recovering all possible otherwise wasted heat and returning it to the cycle is in order and has been done. Thermal and mechanical losses were given the most intense development in order to reduce them to the lowest possible amount. This is ongoing detailed improvement development.

As the Cyclone engine already demonstrates high net cycle efficiency, one becomes aware that any further drastic increase in the operating steam conditions is simply not needed. There is a point where the material costs, durability and complication outweigh the hoped for few points in engine efficiency. One must know when to stop. The engine already is competitive to the IC and Diesel engine and automatic transmission package seen in the modern automobile. Where further development will be seen, is in minimizing thermal, fluid flow and friction losses.

Considering all the advances in the technology that Cyclone Power Technologies Inc. has invented and demonstrated makes this one engine a very suitable candidate for vehicle propulsion, both in passenger cars and interstate trucks. The smooth and quiet operation of this engine would make it most attractive for marine use in yachts. The small versions would make dandy outboard motors, or to power refrigeration, air conditioning or generators in interstate trucks and also in yachts.

THE DEMONSTRATION VEHICLE SELECTION.

The first vehicle to employ the Cyclone engine is critical to how this engine will be received by the motoring press and particularly the automobile enthusiasts and wealthy collectors, the ones who would be the first to purchase such a car, should it be followed by a limited production model.

TESLA Motors entered the automotive world with a very expensive and striking battery electric sports car with blistering acceleration and good contemporary styling. It accomplished exactly what it was intended to do, attract wide spread attention and investors in the company. TESLA has now followed up with a much more practical sedan model and Daimler-Benz has made a major investment in the company. The U. S. Government also gave TESLA Motors a major funding grant. This identical philosophy should be followed when reintroducing the Rankine cycle system in the present automotive world.

Does one choose a sub-compact car like the SMART, or a more reasonable small vehicle such as the Ford Focus, or go further and demonstrate a nice GT vehicle that would be impressive when shown at car exhibits? Would a mid range family sedan be more appropriate? The Cyclone is quite adaptable for any first vehicle use. The package must create a good, usable and desirable vehicle. It also must be a type of vehicle that these automotive enthusiasts can relate to and accept, not some one off fiberglass dream fantasy that cannot be produced at a reasonable cost and fills no real and useful need.

The considered first public application should be a GT vehicle in the author's opinion. These are on the market as production cars right now and many high quality limited production specialty vehicles and kit cars are also available for installation of the Cyclone engine. Such a vehicle attracts attention and press coverage is frequently the result. A converted Mazda MX-5 Miata or a reproduction 427 SC Cobra roadster are suggested as good host vehicles for this first automotive effort, a path the author is investigating Two vehicles that are widely accepted and admired.

Yet, the private automobile may not just be the most important insertion vehicle for reintroducing the Rankine cycle steam engine to the automotive market.

The numerous large interstate trucks like the Peterbilt or Kenworth are in need of a powerful new substitute engine than the present Diesels. Government mandates are already making the purchase of such an engine very costly to the truck owners. Coupled with this is the expansion and restoration of our once mighty railroad industry. This selection too is in need of a new and powerful engine to replace their Diesels. Then comes the private automobile, either a compact small car, a family van or SUV, or some high powered GT for the automotive enthusiasts and collectors. The market is wide open and awaiting a reasonable new power source. This first demonstration must be a grand success.

To date the enthusiast car publications do not even know the Cyclone engine exists and seemingly do not care to be informed. These have huge worldwide sales and are very well read. Most important when one considers introducing such a new power system for the automobile and presents the first installation to the public.

This apparent rejection is an outgrowth of two things; the complete failure of the Government sponsored Clean Air Car program and the bad taste that left regarding any steam car in general and a very serious lack of accurate and detailed technical data for the automobile companies to rely on. They cannot study with confidence what is hidden from them. They cannot report on power systems they do not understand and cannot secure really accurate and up to date information about adn to educate themselves.

The Cyclone Technologies Company should not contemplate producing any complete car on their own. The capital investment, time and production costs are not realistic for a company such as Cyclone. The company should remain as a research and development organization, devoted to widening and perfecting the applications of the Cyclone Rankine cycle engine.

There are a sufficient number of available vehicles on the market, in one form or another, that can easily supply the complete host car at reasonable cost. Be it either a conversion of a production gas car, large truck, or an installation in one of the specialty cars.

Chrysler has visited the company and there was interest shown by GM and Ford. This is not considered to be any intent to adopt the Cyclone at the present time; but only an effort of due diligence by the car companies. The major interstate truck manufacturers are starting to show interest, as their Diesel engines now need high cost pollution control. The overall cost of this exceeds what many of their customers will accept, so some other rugged power source is needed. This one application may become a most serious market for the larger Cyclone engine.

The military have also shown interest in the Cyclone for their age-old and constant need for a multi-fuel engine of light weight, small size and silent operation for battlefield operations and other often classified applications. However, this is something that they constantly have investigated over many years without success. A real need exists and the Stirling cycle engine has not provided any answer.

The company is presently concentrating on their waste heat version of the Cyclone and military use and contracts are already in hand. The adaptability of this version to use solar heat fills a worldwide need for local electric power generation in third world and less developed nations and that is a correct business decision by the company. The automotive applications will be a quiet side development and when testing proves the worth of the concept, shown to the public.

The vehicle adaptation of the Cyclone engine is becoming an important matter and some dramatic demonstration is needed in the immediate future, when one considers the constant outpouring of often conflicting and unwise pollution and fuel economy mandates by Governments. It takes time and effort to make the automobile companies take notice. They need to become well educated to the advantages shown by the Cyclone Rankine cycle engine over the often science fiction and fantasy engineering approaches they now pursue.

The automotive steam engine has been dormant for far too long and the present fuel source and pollution problems do encourage that it be again seriously considered. It does offer a solution if only the automotive companies would take the time to honestly and dispassionately investigate the Rankine cycle engine again in light of the notable advances made in the Cyclone engine. Perhaps this proposed demonstration vehicle may be the key to unlock their interest.

The battery electric was once similarly dismissed; but recent new battery developments have brought this vehicle back into prominence and public awareness and most importantly, sales. The steam car needs this same benefit.

Should a really competent Cyclone installation be done in some nice GT car and testing proves the concept, then there may be interest by the surviving Detroit automobile manufacturers. The Cyclone powered demonstration car is the first priority to accomplish this task.

THE COMPLETE 100-150 HP MK-5 CYCLONE AUTOMOTIVE STEAM ENGINE.